Introduction to the properties of PCBN non-standard cutting tools: Polycrystalline cubic boron nitride (PCBN) cutting tools are specially made according to different workpieces and special requirements of customers. The PCBN composite sheet is welded to the carbide cutter body or the steel cutter body. made knives. Because PCBN tool material has excellent cutting performance, it is especially suitable for machining hardened steel with hardness above HRC45, wear-resistant cast iron, heat-resistant alloy above HRC35, and pearlitic gray cast iron below HRC30, which is difficult to machine with other inserts.

PCBN-PCD grooving tool: It can effectively ensure the precision of the workpiece at high speed and solve difficult machining problems. It is more than 5 times the life of cemented carbide grooving tools. Suitable for precision machining.

PCBN precision turning tool: It has good anti-vibration effect, ensures the roughness and precision of the workpiece surface, and can customize various special-shaped turning tools.

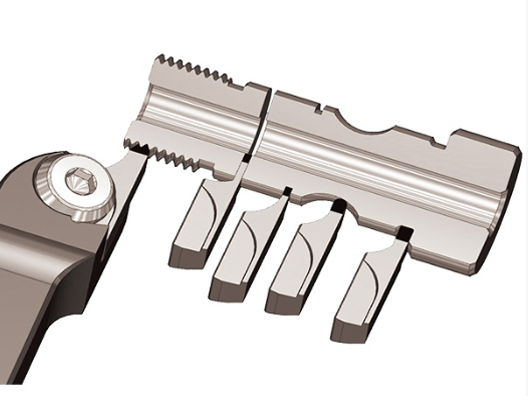

PCBN-PCD thread milling cutter: a large row of thread milling cutters, suitable for rough and fine groove and thread milling.

PCBN grooving cutter: Solve the problem of difficult machining of hard workpieces, mainly used in the automotive and abrasive industries.

PCBN ball end milling cutter: used for groove machining and bearing milling and other industries, the main advantages: the precision and surface roughness of the workpiece are improved, and the service life is far longer than that of cemented carbide.

PCBN milling cutter combination: Use PCBN custom cutters and special cutters to improve the work efficiency of customer plane milling and the highlight and flatness of the workpiece.