Chinese name: Monocrystalline diamond

English name: monocrystalline diamond

Applied discipline: Mechanical Engineering (first-level discipline); Abrasives (second-level discipline); Abrasives (third-level discipline)

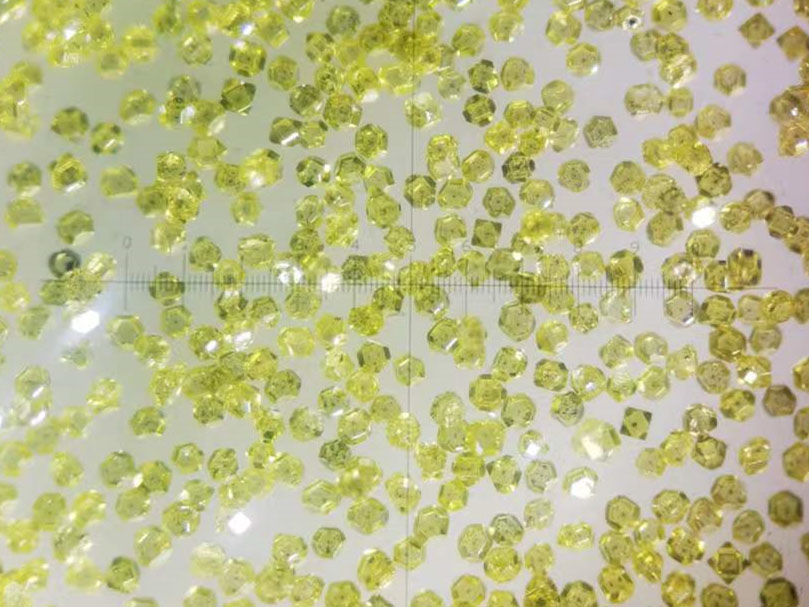

The shape of diamond can be divided into single crystal , conjoined and polycrystals. Single crystals can be further classified into cubes, octahedrons, rhombic dodecahedrons. The picture below shows the crystal form of synthetic diamond, of which the hexahedral form is the most common. Synthetic diamond single crystal is flat, with obvious crystal edges and apex angles.

Hydrostatic catalyst method

It means that under the condition of thermodynamic stability of diamond, it is A method for synthesizing diamond under the conditions of high pressure and high temperature and catalyst participation.

Dynamic pressure method

The dynamic pressure method is mainly the explosion method. The static pressure method of the catalyst is similar (the pressure is generally above 20Gpa), but the method of generating high temperature and high pressure is different, not using a press, but using explosives.

Metastable Growth Method

Metastable growth method is the pressure of the metastable state of diamond. Growth method under temperature conditions. This method does not require high pressure and is often carried out under normal or negative pressure (vacuum).

Machining Industry

Diamond grinding tools are special tools for grinding carbide. When sharpening cemented carbide turning tools, 4-15g of GC abrasive is required for each 1g of metal to be removed, while diamond only consumes 2-4mg.

Electronics and electrical industry

Hard and brittle precious semiconductor materials, such as silicon, germanium, arsenic Gallium, etc., to be made into a chip-shaped semiconductor device, requires cutting and grinding. Currently the most suitable method is to use a diamond cutting saw blade. Polishing semiconductor materials with diamond abrasive paste not only has high efficiency, but also can achieve the highest level of surface roughness Ra0.006um.

Optical glass and gemstone processing industry

Previously, silicon carbide was used to process optical glass, which was inefficient and labor-intensive. Poor condition. Now all diamond grinding tools have been used for processing, including blanking, nesting, cutting, edge grinding and fine grinding of convex and concave surfaces.

Drilling and mining industry

Drilling and mining in petroleum, coal, metallurgy, geological exploration, etc. , widely used diamond bits.

Construction and building materials industry

Cutting in marble, granite, artificial cast stone, concrete building materials For machining and grinding, diamond tools are widely used.