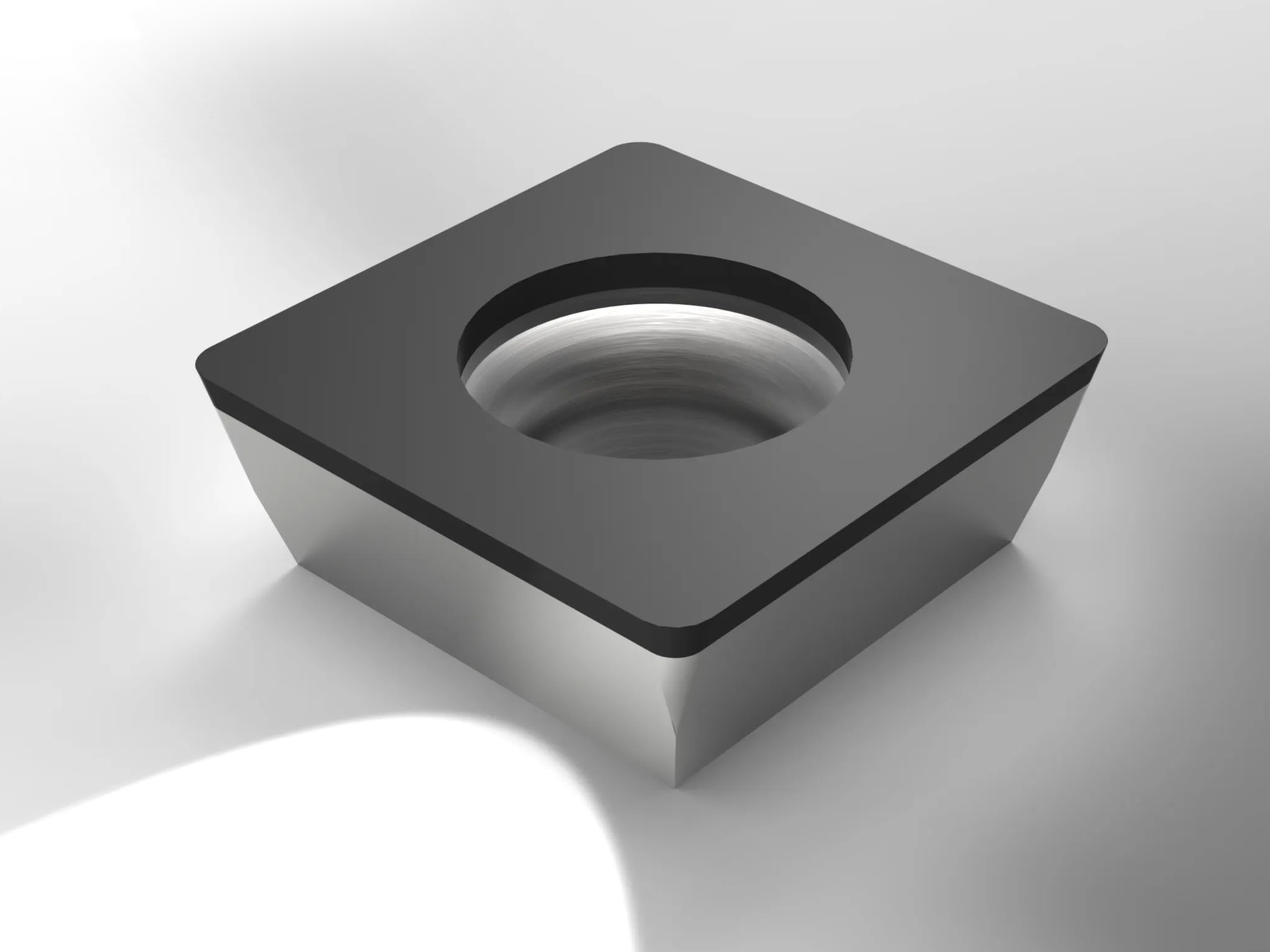

Synthetic polycrystalline diamond composite cutting tool (PCD) is a kind of super hard cutting tool developed in the 1960s. It is second only to natural diamond hardness and wear resistance, low friction coefficient, high thermal conductivity, low coefficient of linear expansion and high composite bending strength, and used in high-speed cutting all kinds of non-ferrous metals, non-metallic. Its tool durability is dozens to hundreds of times that of hard alloy. Our country has successfully developed artificial diamond in the 1960s. On this basis, a layer of polycrystalline diamond is sintered on the hard alloy matrix by high temperature and high pressure technology. In this way, the high hardness and wear resistance of diamond and the toughness of hard alloy are combined. This blade is called artificial polycrystalline diamond composite, or PCD for short.

PCD tool is mainly used for efficient cutting non-ferrous and non-metallic metals. Such as aluminum and aluminum alloy, copper and copper alloy, hard alloy, engineering ceramics, graphite, plastics, rubber, laminates, silicone rubber, babbitt alloy, various composite materials, glass steel and so on. Especially in the automobile manufacturing industry, aerospace, aviation, shipbuilding, engine manufacturing industry, can be widely used.