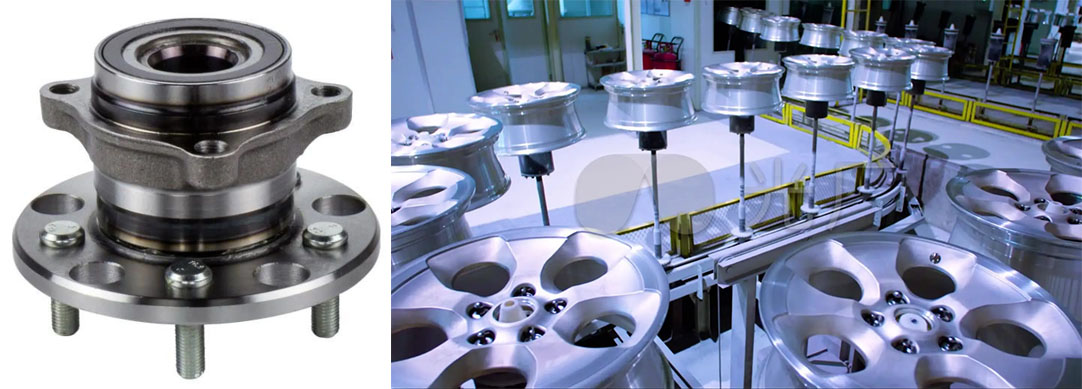

Workpiece name: hub bearing unit; workpiece material: 65Mn; workpiece hardness: 58-63 HRC; machining position: inner hole, raceway.

Workpiece Name: Bearing; Workpiece Material: GCr15; Workpiece Hardness: 58-62 HRC

Rolling bearing is a highly interchangeable standardized component. Due to its different applications, there are various types of bearings. When designing machinery, in addition to selecting a certain type of bearing, it is also necessary to consider the matching of the inner and outer diameters of the selected bearing and other parts, and the cooperation between the outer ring and the housing hole. Therefore, the tolerance of the inner and outer diameters of the bearing should be considered. There are also special requirements for cooperation. The accuracy of the bearing ring is determined by the accuracy of the bearing. The accuracy of the bearing consists of two parts: dimensional accuracy and rotation accuracy. Dimensional accuracy is the item required when the bearing is installed on the shaft or bearing seat, and the rotation accuracy is the error that specifies the runout of the bearing when it rotates. With the development of metal cutting technology, the mechanical processing requirements of bearings in various bearing industries are getting higher and higher, and the application scope of bearings is gradually expanding, such as wind power generation bearings, automobile wheel bearings, aero engine bearings, spherical bearings, etc. The turning of these bearings with special functions and shapes is more suitable for CNC lathes or machining centers with high precision, high efficiency, and multi-surface processing capabilities. Henan Bolairong Superhard Material Co., Ltd. has developed a CBN integral non-standard customized circular arc cutting tool, which is the first in China. The CBN780 cubic boron nitride is synthesized through high temperature and high pressure, and the cutting edge is processed by a precision peripheral grinder in the later stage, which greatly enhances the machinability and improves the durability of the CBN tool.