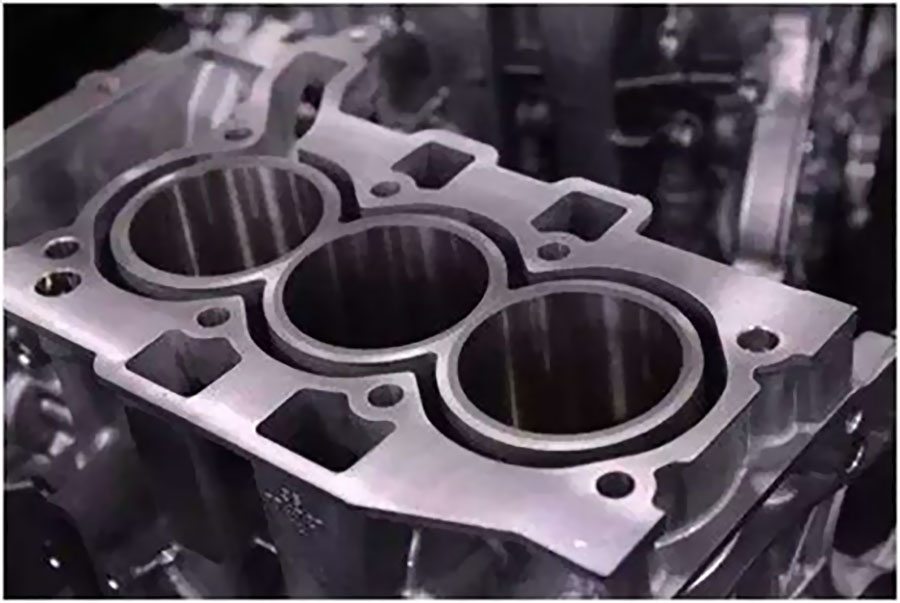

Workpiece name: Three-cylinder engine block; Workpiece material: HT250; Processing position: up and down

Along with people's requirements for car safety and quality in the new era, and car developers' perfect requirements for cars, new processing concepts will also have the opportunity to be verified - PCBN tools and cubic boron nitride Abrasives will be used in semi-finishing and final-finishing operations for next-generation engines, which can be four to eight times more productive than traditional tool materials.

Make the world free from difficult materials.

The super-hard materials designed, developed and manufactured by Brilliant are widely used in the field of precision machining in the automotive industry. Every automotive component requires a stable, sophisticated production process to meet ultimate reliability needs. Element Six superhard materials meet the extreme performance demands of applications such as boring, milling, machining, grooving, reaming, grinding, turning and honing.

Vertical drills are used throughout the entire automotive manufacturing process. In the production of automotive panels, for example, they are used to machine critical engine and transmission components, intermediate shafts, wheel and brake disc assemblies, windows and moulds. Brilliant superhard superhard materials help achieve precise and reliable automotive production processes.

Compared to traditional tool materials, our superhard materials can help engine and powertrain plants around the world achieve more reliable cutting and grinding processes, increasing cutting and grinding speeds, Extend tool life, reduce total operating costs and increase operational efficiency.

Vertical drill superhard cubic boron nitride material is used for grinding cams and crankshafts as well as rough and fine grinding of steel gears.