The superhard materials designed, developed and manufactured by the company are used in precision cutting, milling, drilling and grinding of aerospace components and systems. Brilliant superhard products successfully meet the new and changing demands of the aerospace industry due to the introduction of difficult-to-machine materials such as composites and high-strength metals.

We work closely with our customers to optimize the application of superhard materials in aerospace processing, helping them develop material solutions and creating value for end users. We produce superhard materials that increase cutting speeds and enable the cutting, milling, drilling and grinding of aerospace components. productivity while extending tool life—often orders of magnitude higher than conventional tool materials.

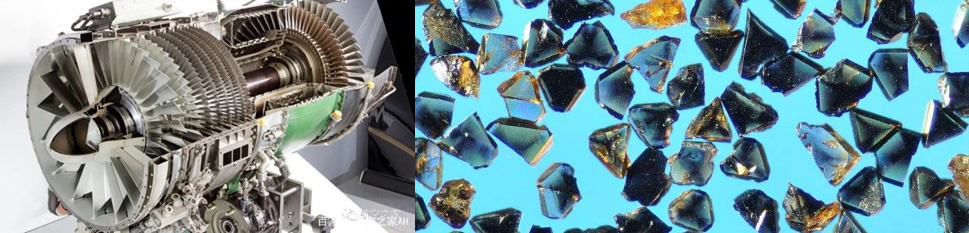

Brilliance Super Hard Cubic Boron Nitride (CBN) material is used to grind turbine blade roots and to machine precise clearances for engine covers. Compared with traditional abrasives, CBN can maintain high hardness and sharpness in a wide temperature range, so it is suitable for processing ferrous materials. The wear resistance of CBN abrasives is two orders of magnitude higher than that of the most common conventional alumina abrasives, thus maintaining shape accuracy for longer. CBN abrasives can greatly improve the grinding efficiency when grinding hardened steel.

Brilliance superhard PCBN (polycrystalline cubic boron nitride) material is increasingly used for semi-finishing of nickel-based superalloy discs and shafts. Today, coated and uncoated cemented carbide tools are widely used in the finishing of nickel- and cobalt-based superalloys at speeds of up to 50 m/min. In contrast, PCBN tools can reliably achieve machining speeds of 300 m/min or higher, enabling longer tool life and promising improved surface quality. PCBN tools can increase productivity by a factor of 6, thereby helping to reduce machine tool investment and operating costs, which is extremely attractive to component manufacturers.

Brilliance superhard materials are used for metal cutting and burr removal of aerospace parts, featuring high performance and long service life. We offer a wide range of carbide burrs blanks to both English and German DIN standards.